Plastic Injection Mouldings

Price 1000- 100000 INR/ Unit

Plastic Injection Mouldings Specification

- Type

- Custom Injection Mouldings

- Material

- Plastic (ABS, PP, PC, Nylon, etc.)

- Shaping Mode

- Injection Mould

- Surface Treatment

- Smooth Finish

- Size

- Customized as per requirement

- Width

- 10 mm to 800 mm (customizable)

- Length

- 10 mm to 1000 mm (customizable)

Plastic Injection Mouldings Trade Information

- Minimum Order Quantity

- 500-5000 Units, ,

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

About Plastic Injection Mouldings

Among all other companies, we are acknowledged as one of the leading manufacturers and exporters of Plastic Injection Mouldings. These mouldings are widely used in the industrial machines for manufacturing different varieties of products in varied sizes and dimensions. We make use of only certified grade plastics for manufacturing these Plastic Injection Mouldings. Before the final delivery in market, all the mouldings are tested for their finish and quality.

Features

- High impact strength

- Crack resistant

- Durable quality

Precision Customisation for Diverse Applications

We specialise in manufacturing custom injection mouldings in a variety of plastics including ABS, PP, PC, and Nylon. Our flexibility in size and shape ensures each part fits your project perfectly, whether used in automotive, electronics, consumer products, or industrial equipment.

Smooth Surface Finish for Enhanced Performance

Each injection moulded component receives a surface treatment that results in a smooth, high-quality finish. This attention to detail not only enhances product aesthetics but also supports better functionality, making the components easier to clean and assemble.

Leading Supplier and Exporter from India

With years of expertise, we have established ourselves as a reliable manufacturer, supplier, and exporter of plastic injection mouldings. Our manufacturing facilities in India are equipped with modern injection moulding machinery, ensuring timely delivery and rigorous quality control.

FAQs of Plastic Injection Mouldings:

Q: How are custom plastic injection mouldings produced?

A: Custom plastic injection mouldings are produced using precision injection moulding machines. Raw plastic (such as ABS, PP, PC, or Nylon) is melted and injected into a customized mould designed according to your required specifications. The part cools and solidifies, before undergoing a smooth surface treatment for a quality finish.Q: What surface treatments are applied to the mouldings?

A: The injection mouldings receive a specialized surface treatment that yields a smooth, refined finish. This treatment improves the products appearance, touch, and functionality, making parts suitable for high-visibility or high-performance applications.Q: When should I consider using custom injection mouldings?

A: Custom injection mouldings are ideal when you require parts with specific dimensions, materials, and finishes that standard products cannot provide. They are particularly useful for industries such as electronics, automotive, and consumer goods manufacturing, where precision and customization are critical.Q: Where are your injection mouldings manufactured and supplied from?

A: Our plastic injection mouldings are manufactured in our advanced facilities located in India. We export and supply these custom products both domestically within India and to international clients across several countries.Q: What is the process for ordering customized injection moulded products?

A: The process starts by sharing your specifications, including material type, dimensions, and finish requirements. We then develop the custom mould, carry out the injection moulding, apply the surface treatment, and perform quality checks before delivering to your location.Q: How can I use these mouldings in my project?

A: These plastic injection mouldings are versatile and can be used in a wide range of products, from automotive components to electronic housings and consumer goods. Their custom sizes and finishes make them easy to integrate into your production processes.Q: What are the benefits of sourcing from an experienced Indian manufacturer and exporter?

A: Sourcing from an experienced Indian manufacturer offers you competitive pricing, reliable quality, and the ability to tailor products to your specific needs. Our capability to handle large-scale orders and export logistics makes us a preferred partner for clients worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

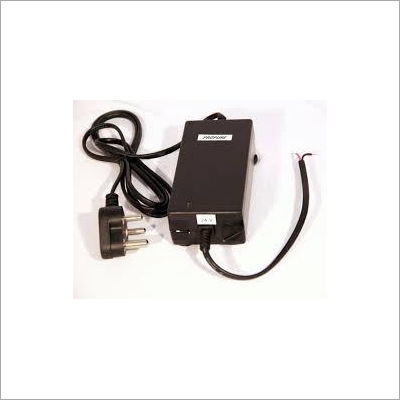

More Products in Water Purifier Parts Category

SMPS Box, 3W to 11 W cabinets,Clamps,Assembly childs parts

Price 21-27 INR / Unit

Minimum Order Quantity : 5005000 Units

Type : SMPS Box Cabinet

Color : Black

Size : 3W to 11W

Shaping Mode : Injection Molding

Water Purifier Parts

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units, ,

Type : Water Purifier Spare Parts

Color : White

Size : Standard Fit

Shaping Mode : Injection Molding

Plastic Injection Moulding Parts

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Type : Plastic Injection Moulding Parts

Color : Black, White, Custom

Size : Customized

Shaping Mode : Injection Mould

Injection Mouldings

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Type : Injection Mouldings

Color : Black, White, Blue, Red, Customized

Size : Customized

Shaping Mode : Injection Mould

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry