Injection Mouldings

Price 1000- 100000 INR/ Unit

Injection Mouldings Specification

- Type

- Injection Mouldings

- Plastic Material

- Customizable as per requirements

- Shaping Mode

- Injection Mould

- Mold Base

- P20 / S50 / 718

- Surface Treatment

- Polished

- Size

- Customized

- Width

- Up to 300 mm

- Length

- Up to 500 mm

- Color

- Black, White, Blue, Red, Customized

Injection Mouldings Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

About Injection Mouldings

We are widely acclaimed in this industry for manufacturing and exporting an excellent stock of Injection Mouldings. These plastic components are available in different sizes and dimensions and can be also customized as per the clients' individual requirements. We make sure to manufacture all these moulding components using high grade plastics. We are offering Injection Mouldings to clients at the competitive prices.

Features

- Crack resistant

- Accurate dimensions

- Durable quality

Superior Surface Polishing

We specialize in polished surface treatments for injection mouldings, ensuring a faultless visual finish and enhanced product performance. This feature is valuable for industries where appearance and smooth surfaces are critical, providing both aesthetic appeal and increased functionality for the final product.

Customizable Options for Your Unique Specifications

Every project has its distinct needs. Our injection mouldings can be tailored in terms of material, size (up to 500 mm x 300 mm), and color, offering flexibility for diverse applications. We advise clients to specify their requirements, ensuring a precise match for their technical and visual standards.

FAQs of Injection Mouldings:

Q: How does surface polishing enhance injection mouldings?

A: Surface polishing removes imperfections and creates a smooth, reflective finish, improving aesthetics and functionality. It also aids in easier part release from the mould and can reduce post-production processing. Polished surfaces are particularly beneficial in visible or contact-end applications.Q: What materials can be used in customized injection mouldings?

A: We offer a range of plastic materials, fully customizable to suit your applications needs. Let us know your material preferences or performance requirements, and our team will source or recommend the ideal plastics for your project.Q: When should I consider using injection mouldings with a P20, S50, or 718 mould base?

A: P20, S50, and 718 mould bases are selected based on their strength, machinability, and wear resistance. They are ideal when you require durable moulds for high-volume or precision parts, particularly with polished finishes for enhanced product quality.Q: Where do you ship your injection moulding products?

A: As a leading exporter, manufacturer, and supplier based in India, we ship our injection moulding products globally. We support both domestic and international clients across various industries, ensuring reliable and timely delivery.Q: What is the typical process for ordering customized injection mouldings?

A: Simply provide us with your specifications for size, color, material, and quantity. Our experts will collaborate with you to refine the design, select the appropriate mould base, and manage the moulding process to deliver high-quality finished parts that meet your exact requirements.Q: How are these injection mouldings typically used?

A: These versatile mouldings serve a broad array of applications, from automotive and electronics to consumer goods. Their customizable nature allows them to function as enclosures, mechanical parts, or decorative components, depending on your projects demands.Q: What are the key benefits of choosing your injection mouldings?

A: Our injection mouldings offer precise customization, polished surface finishes, and robust mould base options, ensuring long-lasting, visually appealing products. Clients also benefit from expert guidance, quality assurance, and flexible production tailored to specific industry needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Purifier Parts Category

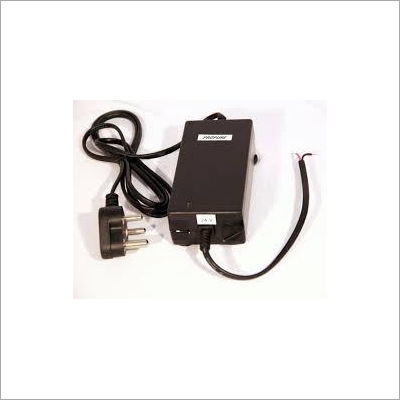

SMPS Box, 3W to 11 W cabinets,Clamps,Assembly childs parts

Price 21-27 INR / Unit

Minimum Order Quantity : 5005000 Units

Type : SMPS Box Cabinet

Material : ABS Plastic

Width : 45 mm

Shaping Mode : Injection Molding

Water Purifier Parts

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units, ,

Type : Water Purifier Spare Parts

Material : ABS Plastic

Width : 5 cm

Shaping Mode : Injection Molding

Plastic Injection Moulding Parts

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Type : Plastic Injection Moulding Parts

Material : ABS, PP, PC, POM, Nylon, or as specified

Width : As per client specification

Shaping Mode : Injection Mould

SMPS Box

Price 17 INR / Unit

Minimum Order Quantity : 5005000 Packs

Type : Electric Enclosure

Material : Mild Steel

Width : 100mm

Shaping Mode : Bending/Welding

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry