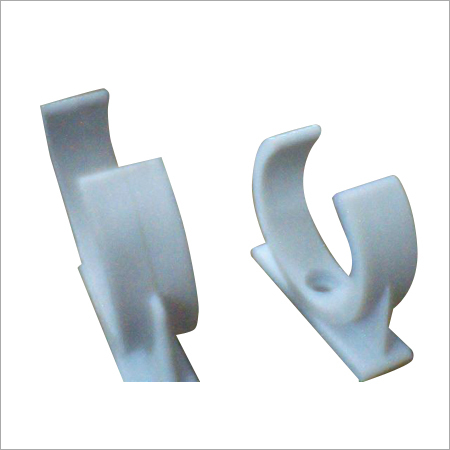

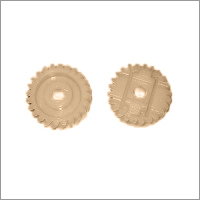

Plastic Injection Moulded Components

Price 1000- 100000 INR/ Unit

Plastic Injection Moulded Components Specification

- Tolerance

- 0.02 mm

- Life Span

- 100,000 shots

- Cavity

- Single or Multiple as per design

- Molding Material

- Thermoplastic & Engineering Plastics

- Precision

- High, up to micron level

- Shaping Mode

- Injection Moulding

- Type

- Custom, OEM/ODM

- Surface Treatment

- Smooth finish, Textured, Polished

- Weight

- 5 g 1000 g

- Size

- Customized as per requirement (10 mm 500 mm)

- Hardness

- Shore D 65 85, material dependent

Plastic Injection Moulded Components Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

About Plastic Injection Moulded Components

Highly acclaimed in the industry, we are acknowledged as the proficient manufacturer and exporter of Plastic Injection Moulded Components. These moulded components are installed in the injection moulding machines for shaping a wide range of plastic products. We make available these components to clients in different sizes and dimensions to choose from. Only superior quality of plastics are used for designing the entire range of Plastic Injection Moulded Components.

Salient Features:

- Accurate dimensions

- Heat resistant

- Smooth finish

- At market leading price

Precision Tailored to Your Application

Every component is manufactured according to your custom specifications, from size and surface finish to material and precision. Whether smooth, polished, or textured, our advanced capabilities support both single and multiple cavity molds and meet the highest standards for accuracy. Our expertise ensures each finished product integrates seamlessly into your production process.

Durable and Versatile Performance

Our injection moulded parts are built to last, achieving a mould life span of 100,000 shots or more. Using top-grade thermoplastics and engineering plastics, these components offer outstanding hardness and durability while remaining lightweight. They are ideal for industries ranging from automotive and electronics to consumer goods and medical devices.

FAQs of Plastic Injection Moulded Components:

Q: How are custom plastic injection moulded components manufactured?

A: Custom plastic injection moulded components are manufactured using high-precision injection moulding machines. The process involves heating thermoplastic or engineering plastic pellets until they melt, then injecting them into customized moulds to achieve the precise shapes, sizes (10 mm 500 mm), and finishes required.Q: What surface treatments and finishes are available for these components?

A: We offer a choice of surface treatments, including smooth finish, textured, and polished options. The final finish is determined by both the mould design and specific customer requirements, ensuring that components meet the aesthetic and functional standards for diverse applications.Q: When should I choose injection moulded components for my project?

A: Injection moulded components are ideal when you require high-precision, customized parts with strict tolerances, consistent quality, and repeatability for medium to large production runs. Our solutions are particularly suitable for OEM/ODM applications needing parts weighing from 5 g up to 1000 g.Q: Where do you export and supply your moulded components?

A: We export and supply our custom plastic injection moulded components globally, with a solid presence as a manufacturer, exporter, and supplier based in India. Our flexible manufacturing supports clients in automotive, electronics, medical, and other industries worldwide.Q: What is the typical process and lead time for developing a new custom component?

A: The typical process includes client consultation, design finalization, material selection, mould fabrication, sample validation, and production. Lead times vary depending on design complexity and order volume but are optimized to reduce turnaround while ensuring high quality.Q: How can these precision components benefit my business?

A: These high-precision injection moulded parts offer excellent dimensional stability, reliable repeatability, and smooth or customized surface finishes. They reduce assembly time, improve product consistency, and enhance the durability and performance of your final products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulded Components Category

Moulded Plastic Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Molding Material : Thermoplastic

Precision : High Precision

Type : Other, Moulded Plastic Components

Weight : As per design

Moulded Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units, ,

Molding Material : Thermoplastic

Precision : High Precision

Type : Other, Moulded Components

Weight : As Per Design

Chutney lid

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Molding Material : PP (Polypropylene)

Precision : High Precision

Type : Other, Disposable Round Lid

Weight : 2g 4g (Depending on Lid Size)

Injection Moulded Plastic Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Molding Material : ABS, PP, PC or as specified

Precision : High Precision

Type : Other, Industrial, Custom

Weight : As per customized size/specification

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry