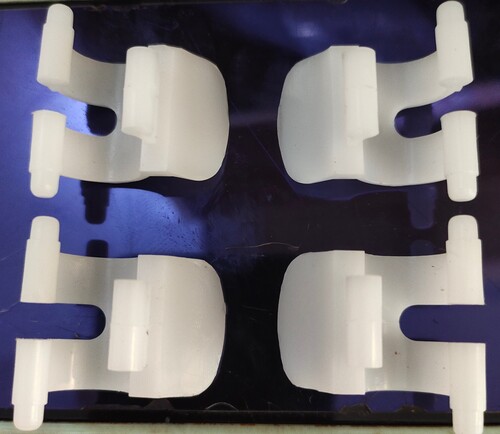

Injection Moulded Plastic Components

Price 1000- 100000 INR/ Unit

Injection Moulded Plastic Components Specification

- Cavity

- Single/Multiple as per design

- Tolerance

- 0.05 mm

- Life Span

- 300,000 to 1,000,000 shots

- Molding Material

- ABS, PP, PC or as specified

- Precision

- High Precision

- Shaping Mode

- Injection Moulded

- Type

- Industrial, Custom

- Surface Treatment

- Texture/Polished/Matte

- Weight

- As per customized size/specification

- Size

- Customized as per requirement

- Runner System

- Hot Runner/Cold Runner

- Production Capacity

- Up to 50,000 pieces per month

- Application

- Automotive, Electronics, Medical Devices, Consumer Goods

- Eco-Friendly Options

- Available on Request

- Color Options

- Available in Black, White, Grey, and Custom Colors

- Finish

- Glossy, Matte, Textured or Custom

- Design Support

- 3D CAD, Prototyping Available

Injection Moulded Plastic Components Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

About Injection Moulded Plastic Components

Relying on our years of experience in this industry, we are known to be one of the leading entities, engaged in manufacturing and exporting an excellent stock of Injection Moulded Plastic Components. These components are highly appreciated for their supreme finish and wide usage in manufacturing plastic products. Tested on their quality and durability, the Injection Moulded Plastic Components are offered in market at the cost effective prices.

Key Features:

- Durable quality

- High impact strength

- Zero defects

- At the cost effective prices

Customizable Color and Finish Options

Choose from a diverse palette including black, white, grey, and custom colors. Our surface treatments allow further personalization, offering glossy, matte, textured, or even completely custom finishes to match your applications exact requirements.

Applications Across Multiple Industries

Our injection moulded components serve sectors such as automotive, electronics, medical devices, and consumer goods. Tailored for industrial and custom use, we ensure components meet precise specifications, supporting a broad range of product designs and functions.

Precision Engineering and High Production Capacity

Utilizing advanced 3D CAD design and prototyping, we ensure every part matches your specifications with high precision (0.05 mm tolerance). Our facilities are equipped to produce up to 50,000 pieces per month, accommodating single or multiple cavity mould requirements.

FAQs of Injection Moulded Plastic Components:

Q: How are custom colors and surface finishes achieved for injection moulded components?

A: Custom colors are incorporated by using colorants or pigments blended with base materials before injection moulding. Surface finishes such as glossy, matte, or textured are achieved through specialized mould design and surface treatments, tailored for each clients specifications.Q: What is the production process for these injection moulded components?

A: The process begins with 3D CAD design and prototyping to confirm the component meets your requirements. Using injection moulding machines with either hot or cold runner systems, molten plastic is injected into precision-engineered moulds, which are then finished according to the desired surface aesthetics.Q: Where can these injection moulded parts be used?

A: These components are widely used in automotive systems, electronic enclosures, medical device housings, and consumer goods, thanks to their versatility, accuracy, and customizable properties.Q: What are the benefits of using high-precision injection moulded components?

A: High precision ensures consistent quality, dimensional accuracy (0.05 mm tolerance), reliable performance, and improved assembly in end-use applications. It also reduces material waste and the need for post-processing.Q: When should I opt for prototyping before full-scale production?

A: Prototyping is recommended when validating a new design, testing fit and function, or before investing in final production tooling. It helps identify and resolve potential issues early, ensuring optimal results in mass production.Q: What eco-friendly options are available for these plastic components?

A: Eco-friendly alternatives include using recyclable or biodegradable plastics, incorporating recycled content, and optimizing moulding processes to minimize waste. These options are available upon request to help meet sustainability targets.Q: How does the runner system (hot or cold) affect production?

A: Hot runner systems reduce material waste and cycle times by keeping plastic molten inside the mould, enabling faster production and better surface finishes. Cold runner systems are more cost-effective for lower volumes, though they can generate more material scrap. The choice depends on project scale and design needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulded Components Category

Molded Plastic Filters

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units, ,

Shaping Mode : Other, Plastic Injection Mould

Precision : High Precision Molding

Molding Material : Engineering Grade Plastic

Surface Treatment : Smooth Finish

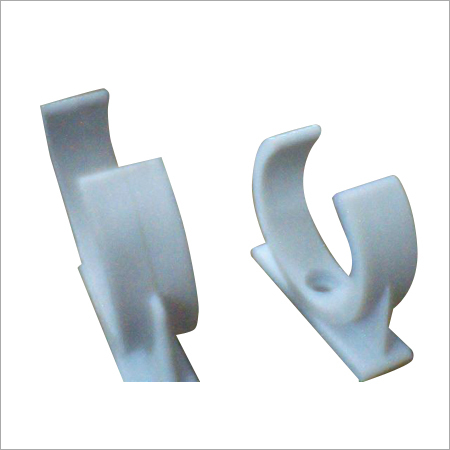

Plastic Moulded Jar Locking Clip

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Shaping Mode : Other, Plastic Injection Mould

Precision : High Precision Moulding

Molding Material : Virgin Plastic

Surface Treatment : Smooth Finish

Plastic Injection Moulded Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Shaping Mode : Other, Injection Moulding

Precision : High, up to micron level

Molding Material : Thermoplastic & Engineering Plastics

Surface Treatment : Smooth finish, Textured, Polished

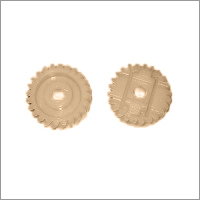

Chutney lid

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Shaping Mode : Other, Injection Mould

Precision : High Precision

Molding Material : PP (Polypropylene)

Surface Treatment : Glossy Finish

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry