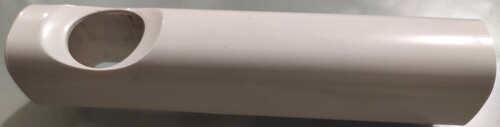

Plastic Die Moulds

Price 100000 INR/ Unit

Plastic Die Moulds Specification

- Tolerance

- 0.01 mm

- Life Span

- 200,000 to 1,000,000 Shots

- Working Process

- CNC Machining, EDM, Polishing

- Mould Base

- P20 Steel / S50C (Customizable)

- Material

- Plastic, Steel (as Per Application)

- Shaping Mode

- Plastic Injection Mould

- Die Head

- Precision Hardened Steel

Plastic Die Moulds Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 7 Days

About Plastic Die Moulds

To assure the excellent performance, we bring forth a wide range of Plastic Die Moulds.Widely demanded in the plastic and manufacturing industry,these moulds are rigorously checked on various parameters. Broadly used for designing various plastic products, these die molds are highly acknowledged in the market for their sturdy structure and corrosion resistant finish. Manufactured in compliance with set industry standards, these Plastic Die Moulds can be availed from us in varied standard specifications.

Features:

- Low maintenance

- Easy to install

- Long working life

Precision Engineering for Longevity

Our plastic die moulds are engineered to deliver consistent, high-quality output throughout their lifespan. With a base of P20 Steel or S50C and precision-hardened die heads, they maintain their accuracy for hundreds of thousands to a million cycles, minimizing downtime and maintenance.

State-of-the-Art Manufacturing

We employ CNC machining, Electrical Discharge Machining (EDM), and meticulous polishing to achieve tight tolerances of 0.01 mm. This rigorous process guarantees each mould adheres to strict quality standards, supporting even the most demanding plastic injection needs.

Tailored for Versatile Applications

Our moulds are customizable with both material and shaping mode options to fit various industrial requirements. Whether you need plastic, steel, or a specific design, we adjust specifications based on client application, ensuring flexibility and optimal results in every project.

FAQs of Plastic Die Moulds:

Q: How are plastic die moulds customized to suit different applications?

A: We customize our plastic die moulds by offering various mould base materials such as P20 Steel or S50C and selecting plastic or steel as required for your application. Our expert engineering team works with you to determine the optimal specifications, including tolerance, shaping mode, and mould life, to meet your precise production requirements.Q: What is the typical process for manufacturing these moulds?

A: The manufacturing process for our plastic die moulds involves precise CNC machining, advanced Electrical Discharge Machining (EDM), and thorough polishing. Each step ensures accurate dimensions, smooth surfaces, and compliance with the tight tolerance of 0.01 mm for consistently high-quality output.Q: When should you choose a mould base of P20 Steel over S50C?

A: P20 Steel is typically selected for moulds that require high durability, longer lifespan, and superior polishability, making it ideal for large volume production. S50C, while reliable, is usually used for less demanding applications or lower-volume projects where cost-effectiveness is a priority.Q: Where are your plastic die moulds exported and supplied from?

A: We manufacture and supply our plastic die moulds from India, catering to a global clientele. As an exporter, manufacturer, and supplier, we serve industries both domestically and internationally, ensuring timely delivery and quality assurance wherever you are located.Q: What are the advantages of using precision hardened steel for the die head?

A: Utilizing precision hardened steel for the die head provides exceptional wear resistance, consistent dimensional stability, and a longer operational lifespan. This ensures the mould maintains its performance over high-volume production runs, reducing replacement frequency and saving costs.Q: How does the moulds lifespan range impact its usage and value?

A: With a lifespan ranging from 200,000 to 1,000,000 shots, our moulds are suitable for both medium and high-volume manufacturing. This extended life reduces downtime, replacement costs, and ensures consistent production quality, providing significant value to your operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulds Category

Plastic Moulded Hand shower

Price 20 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Plastic

Shaping Mode : Other, Injection Moulding

Toy doll

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Material : Plastic

Shaping Mode : Plastic Mould

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry