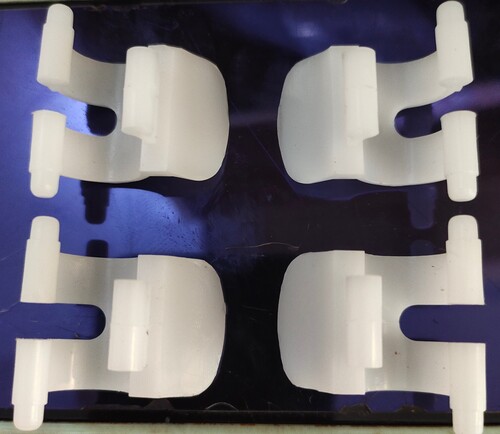

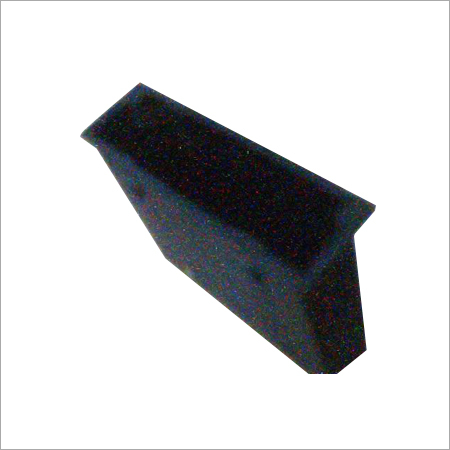

Industrial Plastic Moulded Components

Price 1000- 100000 INR/ Unit

Industrial Plastic Moulded Components Specification

- Cavity

- Single/Multiple

- Tolerance

- 0.02 mm

- Precision

- High Precision

- Life Span

- Up to 1,000,000 shots

- Mold Base

- Steel

- Shaping Mode

- Injection Moulding

- Material

- High Impact Plastic

- Type

- Industrial Moulded Component

- Surface Treatment

- Smooth Finish

- Weight

- Depends on design; ranges from 50g to 2kg

- Size

- Customizable

- Color

- Black, Grey, or as per requirement

- Customization

- Detailed CAD drawings accepted

- Environmental Compliance

- RoHS and REACH compliant

- Impact Strength

- High

- Flame Retardant

- Available upon request

- Usage

- Machine Parts, Automotive, Electronics Housings

- Packaging

- Standard export packaging

Industrial Plastic Moulded Components Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

About Industrial Plastic Moulded Components

Supported by experienced professionals, we are manufacturing and supplying an excellent range of Industrial Plastic Moulded Components. These are widely installed in various industrial machines for their smooth functioning. Manufactured using innovative technology in compliance with set industry standards, the molded components are easy to install and rust proof. These Industrial Plastic Moulded Components are available in different specifications to cater the needs of our valuable clients. Moreover, these are sternly checked on various parameters.

Features:

- Low maintenance

- Sturdy design

- Long working life

Versatile Customization and High Precision

With detailed CAD drawings, we offer fully customizable Industrial Plastic Moulded Components that meet precise design requirements. Our injection moulding process delivers parts with a high precision of 0.02 mm and a smooth surface finish, supporting complex or intricate industrial applications. Each component can be tailored in color, size, and weight, ensuring your unique project needs are met effectively.

Compliance with Stringent Industry Standards

Our products are manufactured with strict adherence to RoHS and REACH compliance guidelines, ensuring environmental responsibility. Flame retardant properties can be included upon request, making these components suitable for safety-critical uses. This makes them an ideal choice for industries that demand both high performance and adherence to international regulatory standards.

FAQs of Industrial Plastic Moulded Components:

Q: How are the industrial plastic moulded components manufactured?

A: These components are produced via advanced injection moulding using high-impact plastic, ensuring high precision and consistent quality. The use of steel molds allows for both single and multiple cavity designs, supporting efficient and scalable production.Q: What customization options are available for these components?

A: We accept detailed CAD drawings, enabling full customization of size, color (black, grey, or specific requirements), surface treatment, and design specifications. Weight and other characteristics can also be tailored based on the project needs.Q: When can flame retardant properties be incorporated into the components?

A: Flame retardant features are available upon request during the ordering process, allowing you to meet specific safety or regulatory standards required for your application.Q: Where are these components typically used?

A: Our moulded components are utilized across various industries including machine parts, automotive assemblies, and electronics housingsoffering robust solutions due to their high impact strength and precise tolerances.Q: What is the usual process for ordering and manufacturing customized parts?

A: Customers provide detailed CAD drawings outlining their requirements. Following design confirmation, we manufacture the components using injection moulding and deliver them in standard export packaging, ensuring safe and timely delivery worldwide.Q: What are the main benefits of using high-impact, RoHS and REACH compliant plastic components?

A: Choosing our components ensures durability, environmental safety, and regulatory compliance. Their high impact strength and longevityup to 1,000,000 shotsmake them reliable for demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulded Components Category

Pump Moulded Parts

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Size : Custom or Standard Sizes Available

Material : Other, Engineering Plastic

Shaping Mode : Other, Injection Moulding

Molding Material : Polypropylene, Nylon, ABS

Textile Plastic Moulded Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Size : Customized as per requirement

Material : Other, High Strength Engineering Plastic (e.g. Nylon, Polypropylene, ABS)

Shaping Mode : Other, Plastic Injection Mould

Molding Material : Virgin Grade Plastic Polymers

Plastic Moulded Jar Locking Clip

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Size : Standard (fits most plastic jars)

Material : Other, Polypropylene (PP)

Shaping Mode : Other, Plastic Injection Mould

Molding Material : Virgin Plastic

Chutney lid

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Size : Customized (Common sizes range from 60mm to 95mm)

Material : Other, Food Grade Plastic

Shaping Mode : Other, Injection Mould

Molding Material : PP (Polypropylene)

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry