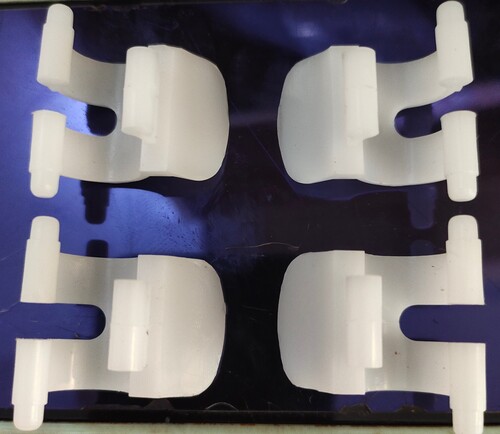

Pump Moulded Parts

Price 1000- 100000 INR/ Unit

Pump Moulded Parts Specification

- Precision

- High Precision

- Molding Material

- Polypropylene, Nylon, ABS

- Cavity

- Single/Multiple

- Mold Base

- Steel

- Tolerance

- 0.05 mm

- Life Span

- Depends on usage, typically >100,000 cycles

- Shaping Mode

- Injection Moulding

- Material

- Engineering Plastic

- Type

- Pump Moulded Component

- Surface Treatment

- Smooth Finish

- Weight

- Variable as per design

- Size

- Custom or Standard Sizes Available

Pump Moulded Parts Trade Information

- Minimum Order Quantity

- 500-5000 Units

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 7 Days

About Pump Moulded Parts

We are growing remarkably in this industry by manufacturing and exporting an excellent range of Pump Moulded Parts. These parts are designed using the best quality of materials and then moulded for complex shapes and perfect finish. Offered in different dimensions and sizes, these moulded parts are used in different models of pumps for their effective functioning. Prior to the dispatch, these Pump Moulded Parts are tested on their quality.

Key Attributes:

- Excellent Design

- Water proof

- Durable quality

- High quality materials used for making

High Precision Injection Moulded Pump Components

Our pump moulded components are fabricated through advanced injection moulding, ensuring precise dimensions and tight tolerances. The use of engineering plastics like polypropylene, nylon, and ABS enhances durability and performance. With options for both single and multiple cavity designs, we cater to varied production requirements, maintaining quality and repeatability across all batch sizes.

Customisable Sizes and Superior Surface Finishing

We provide both custom and standard sizes, ensuring compatibility with various pump models and engineering needs. Each component undergoes a surface treatment for a smooth finish, reducing friction and extending pump life. Our manufacturing capabilities allow us to deliver parts with exact specifications, supporting client needs for seamless integration and optimal functionality.

FAQs of Pump Moulded Parts:

Q: How are pump moulded parts manufactured using injection moulding?

A: Pump moulded parts are produced by injecting molten engineering plastics, such as polypropylene, nylon, or ABS, into precision steel molds. This process enables the creation of complex shapes with high dimensional accuracy and a smooth surface finish.Q: What benefits do high precision and smooth finish provide in pump moulded components?

A: High precision ensures each part fits perfectly into pump assemblies, reducing the risk of leakage and improving efficiency. The smooth finish enhances flow dynamics, minimizes wear, and extends the overall lifespan of the pump.Q: When should I opt for custom sizes over standard sizes?

A: Custom sizes are ideal when your pump design has specific dimensional requirements or when replacing unique components not readily available off-the-shelf. Standard sizes suit most common pump models.Q: Where are your pump moulded parts typically used?

A: Our components are used in a wide range of pumps for industrial, commercial, and domestic applications, including water pumps, chemical transfer pumps, and specialty machinery requiring precise engineering plastic parts.Q: What is the typical lifespan of these injection moulded pump parts?

A: The life span typically exceeds 100,000 cycles, but it depends on factors such as material choice, operating conditions, and regular maintenance of the pump system.Q: How does the multi-cavity option benefit my production requirements?

A: Multi-cavity molds allow for the simultaneous production of multiple parts, increasing efficiency, reducing lead times, and lowering per-part manufacturing costs, especially beneficial for large-scale projects.Q: What processes ensure quality and precision in your pump moulded components?

A: Our manufacturing involves strict quality control at every step: from material selection to precise mold fabrication and thorough product inspection, ensuring tight tolerances and consistency in every part we deliver.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulded Components Category

Moulded Plastic Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Precision : High Precision

Shaping Mode : Other, Injection Molding

Type : Other, Moulded Plastic Components

Size : Customizable

Plastic Moulded Jar Locking Clip

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Precision : High Precision Moulding

Shaping Mode : Other, Plastic Injection Mould

Type : Other, Jar Locking Clip

Size : Standard (fits most plastic jars)

Industrial Plastic Moulded Components

Price 1000- 100000 INR / Unit

Minimum Order Quantity : 5005000 Units

Precision : High Precision

Shaping Mode : Other, Injection Moulding

Type : Other, Industrial Moulded Component

Size : Customizable

Chutney lid

Price 50 INR / Piece

Minimum Order Quantity : 100000 Pieces

Precision : High Precision

Shaping Mode : Other, Injection Mould

Type : Other, Disposable Round Lid

Size : Customized (Common sizes range from 60mm to 95mm)

|

R. P. ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry